SUPER METERING PUMP (SMP)

The Super Metering Pump (SMP) is a pulse-free metering pump designed to feed liquids with ultra-precision. Developed through Life Sciences’ innovative design expertise and advanced manufacturing, the SMP delivers unmatched accuracy in liquid control and feeding. When precision matters, Life Sciences provides the solution.

KEY FEATURES

- High accuracy: Discharge precision of ±0.1% or better across the specified flow range — even more accurate than a flowmeter.

- Consistent flow: Maintains a steady flow rate despite varying discharge pressures.

- Proportional control: Flow rate is directly proportional to pump speed.

- Pulse-free: Reciprocating mechanism ensures smooth, pulse-free performance.

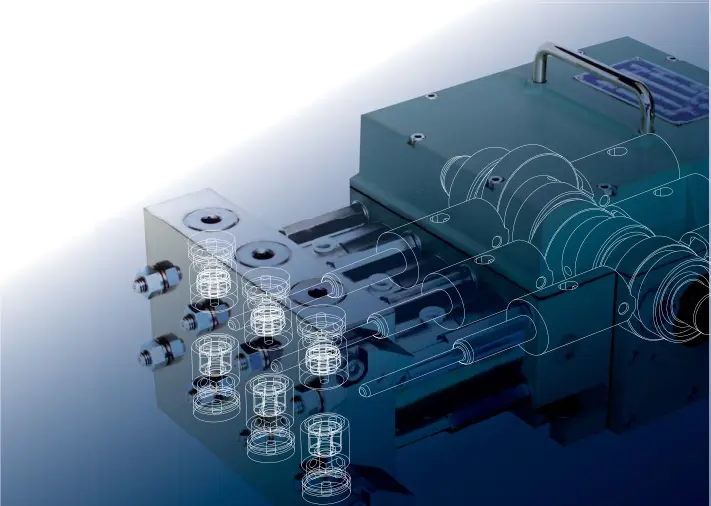

STRUCTURE & DESIGN

Specially Designed Triplex-Plunger Drive

- Three specially engineered cams drive three plungers, maintaining constant discharge volume at all times.

- Each plunger operates at three different speeds, ensuring uniform flow and preventing cavitation.

- Smooth check valve ball movement minimizes pulsation and reduces wear.

- Ultra-precise machining of cams and liquid-end parts (micron-level processing) guarantees ±0.1% flow reproduction.

Mechanical Return System

- Cam-driven mechanical return ensures precise reciprocating plunger movement, making suction and discharge volumes identical.

- No stroke delay, even at high speeds or with viscous fluids.

- Exclusive Life Sciences triplex-plunger drive (HY Series) delivers unmatched durability and accuracy.

APPLICATIONS

- Line mixing & emulsification: Enables instantaneous mixing/homogenization in feed lines without batch systems.

- Precision coating: Ensures uniform coatings (dip/roll) with no pulsation, bubbles, or pressure fluctuation issues.

- Precision cleaning, spraying & spray drying: Stable discharge regardless of back-pressure variations, ideal for viscous environments.

- Additive feeding to extruders: Delivers consistent additive/foaming agent dosing, resulting in uniform particle sizes.

- Dosing lines: Achieves highly precise dosing when paired with servo motor position control.

OPTIONS & VARIANTS

- Temperature Jacket: Controls liquid temperature.

- Liquid purge: Cleans seals between operations.

- Gas purge: Safely handles water-reactive liquids.

- Dual-head system: Doubles flow capacity.

SPECIAL CONFIGURATIONS

- Metal-free specification: Suitable for corrosive liquids or iron-free applications.

- Precision feeding unit “Iretaro”: A mobile, tank-integrated SMP system with control board for flexible operations.

- LCD Injector: Precisely feeds liquefied CO₂ for plastic foaming, with temperature regulation.

- Portable unit: Ready-to-use SMP (HYM model) with motor, speed controller, and touchscreen interface.

- Control system: Dedicated software for managing up to 5 pumps remotely via PC.